Product category

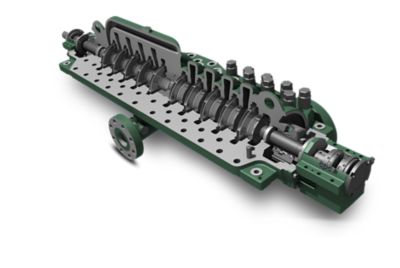

Model HM (BB3)

Overview: HM/HMD (BB3) hydrocarbon pump → fully compliant with API 610 requirements:

Operating Parameters:

flow rate

4,400 US gpm (1,000 m³/h)

Temperatures

400 °F (200 °C)

differential heads

7,600 ft (2,300 m)

Standard Design Working Pressure

2,250 psig (15,000 kPaG)

Download section

CPC HM BB3 PUMP BROCHURE

CPC HM BB3 PUMP BROCHURE

- Filename

- CPC_Pumps-BB3.pdf

- Size

- 465 KB

- Format

Standard Features

- Wide hydraulic coverage

- Application tailored hydraulic selections

- 600/900/1500# flange ratings

- Available in all API 610 Table H-1, S-4 through D-2 materials

- Hydraulically opposed impeller arrangement for thrust balancing

- Single-suction first stage (HM) or double-suction first stage (HMD)

- Axially split, precision milled parting flanges

- Split case wear rings and center bushings for ease of maintenance

- Integral balance line

- Inpro/Seal bearing housing closures

- Heavy Duty baseplate, drip rim or drip pan designs

Optional Features

- High pressure special casing design

- Positive retention of impellers in both directions

- Fan/Heat-sink bearing housing cooling arrangement for operation at elevated temperatures, to eliminate the need for cooling water

- Magnetic bearing housing isolators

- All bearing combination arrangements are available where suitable: Ball/Ball, Sleeve/Ball, Tilt Pad/Sleeve

Typical Applications for the HM (BB3) Hydrocarbon Pump

- Used for Boiler Feedwater, Water Injection, Amine, and many other applications in the hydrocarbon production and processing industry.

| Technical property | Value |

|---|---|

| Max capacity | 4,400 US gpm |

| 1,000 m³/h | |

| Max Head | 7,600 ft |

| 2,300 m | |

| Max Temperature | 400 °F |

| 200 °C | |

| St. Pressure | 2,250 psig |

| 15,000 kPaG | |

| Opt. Pressure | 3,900 psig |

| 26,000 kPag |